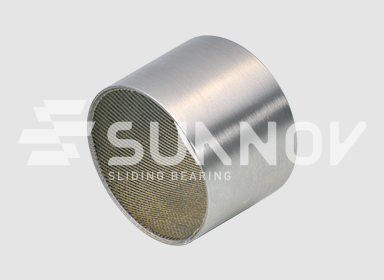

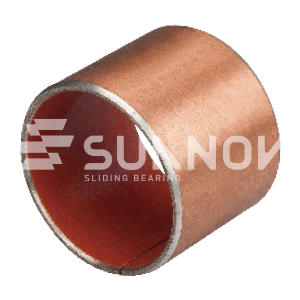

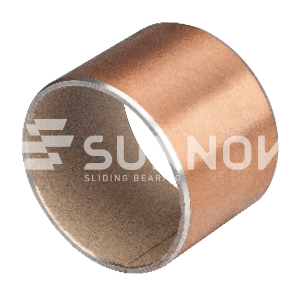

SF-TEX product description

The material is based on various high-quality metals, and the surface is covered with low-friction and wear-resistant braided materials based on PTFE and other additives. This material structure has higher bearing capacity and longer service life than general three-layer composite materials. The base material is low carbon steel (SF-TEX), stainless steel (SF-TEX3), copper (SF-TEXB), etc.

| Code |

SF-TEX |

|

| Material | Stainless steel + polytetrafluoroethylene (PTFE) and abrasion resistant braid | |

| maximum bearing pressure | static load N/mm2 | 250 |

| running at low speed N/mm2 | 140 | |

| Rotation, rocking motion N/mm2 | 60 | |

| Maximum PV value (dry friction) | intermittent operation N/mm2·m/s | 3.6 |

| long-term operation N/mm2·m/s | 1.8 | |

| Maximum line speed | dry rub m/s | 2 |

| fluid lubrication m/s | >2 | |

| Operating temperature °C | -195℃~+280℃ | |

| friction coefficientμ | 0.05~0.20 | |

| Thermal ConductivityW/mk | 42 | |

| coefficient of linear expansion | 11✕10-6· k-1 | |

Main application areas

At present, the product has been used in agricultural machinery, construction machinery, automobile and locomotive chassis parts, ball valves, butterfly valves, various valves, water pumps and chemical industries where heavy loads and low speeds cannot be refueled.