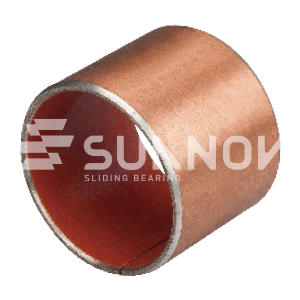

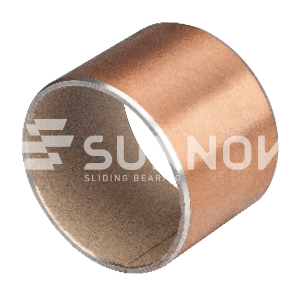

SF-1B product description

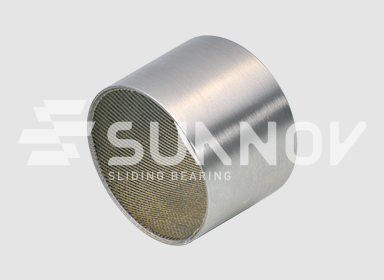

SF-1B bronze base bearing is made of tin bronze as the matrix, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature resistant filling material on the surface. It has a high safety factor, and is especially suitable for places where continuous work cannot be stopped for repairs and places where high temperature cannot be refueled.

| Code |

SF-1B |

|

| Material | Copper+Copper powder+PTFE | |

| Maximum bearing pressure | static load N/mm2 | 250 |

| Low speed operation N/mm2 | 140 | |

| Rotation, rocking motion N/mm2 | 60 | |

| Maximum PV value (dry friction) | intermittent operation N/mm2·m/s | 3.6 |

| long-term operation N/mm2·m/s | 1.8 | |

| Maximum line speed | dry rub m/s | 2 |

| fluid lubrication m/s | >2 | |

| Operating temperature °C | -195℃~+280℃ | |

| friction coefficient μ | 0.05~0.20 | |

| Thermal Conductivity W/mk | 42 | |

| coefficient of linear expansion | 11✕10-6· k-1 | |

Main application areas

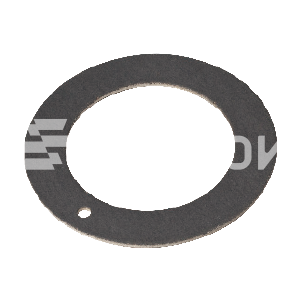

At present, the product has been used in metallurgical steel industry, billet raceway of continuous caster, front equipment of high temperature furnace, cement grouting pump and screw conveyor. It can be combined with a steel sleeve on the outside, or can be made into a flanging, to achieve the effect of friction and use of the end face and the inner hole at the same time.