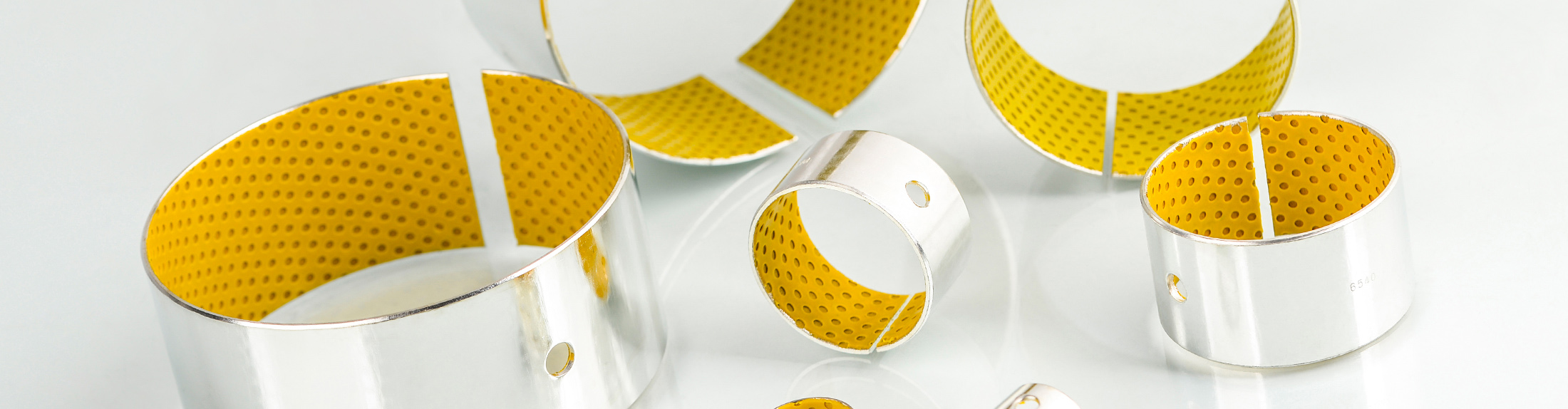

SF-2 product description

SF-2 carbon steel-based boundary self-lubricating bearing is based on steel plate, sintered spherical bronze powder in the middle, surface-rolled modified polyoxymethylene (POM), and contains an oil storage pit. It is suitable for low-speed and medium-load places under normal temperature conditions, replacing traditional copper sleeves to reduce costs and prolong service life. Used on rolling mills, it can save the frequency of refueling and simplify the replacement procedure.

| Code |

SF-2 |

|

| Material | Carbon Steel+Copper Powder+(POM+Pb) | |

| maximum load pressure | static load N/mm2 | 140 |

| dynamic load N/mm2 | 70 | |

| Maximum line speed m/s | Grease lubrication | 2.5 |

| Maximum PV value N/mm2 · m/s | 2.8 | |

| friction coefficient u | 0.06~0.12 | |

| Matching shaft diameter | Hardness HB | >270 |

| Roughness Ra | 0.4~1.25 | |

| Max temperature °C | -60~+120 | |

| Thermal Conductivity W/mk | 52 | |

| Linear expansion coefficient (axial) | 11✕10-6 /k | |

Main application areas

At present, the product has been used in automobile chassis, forging machine tools, metallurgical mining machinery, construction machinery, water and electricity, steel rolling industries and other fields.