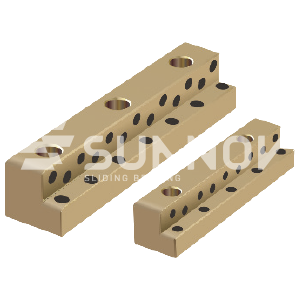

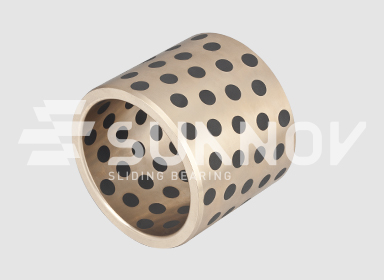

JDB-5 product description

JDB-5 steel-based lubricated embedded bearing is a reinforced product with high compression resistance. It can discharge lubricating particles during operation, so that a diaphragm is formed between the shaft and the sleeve, which is more resistant to single oil lubrication. The advantage of occlusal is especially suitable for the support part of the hoisting machinery. For example: rolling field machine support, crane support, but not suitable for use in water or acid and alkali occasions.

| code |

JDB-5 |

|

| Material | Steel/Gcr15+Graphite | |

| Density g/cm2 | 7.8 | |

| Hardness HB | HRC>58 | |

| Tensile Strength N/mm2 | >1500 | |

| Yield Strength N/mm2 | >15 | |

| Elongation % | >15 | |

| coefficient of linear expansion 10-5/°C | 1.1 | |

| Thermal Conductivity W(/m.k) | — | |

| Elasticity coefficient KN/mm2 | — | |

| Operating temperature °C |

-40~+400 |

|

| Max dynamic load N/mm2 | 150 | |

| Maximum line speed m/s | dry rub | — |

| oil lubrication | 1.0 | |

| Maximum PV N/mm2 · m/s | dry rub | 0.8 |

| oil lubrication | 1.55 | |

| friction coefficientμ | dry rub | 0.13-0.2 |

| oil lubrication | 0.04-0.08 | |

Main application areas

At present, this product has been used in the support parts of lifting machinery, rolling machine support, and crane support, but it is not suitable for use in water or acid and alkali occasions.