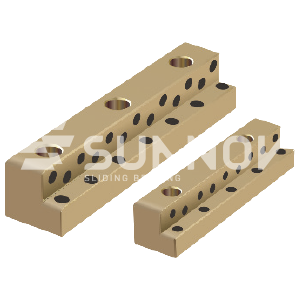

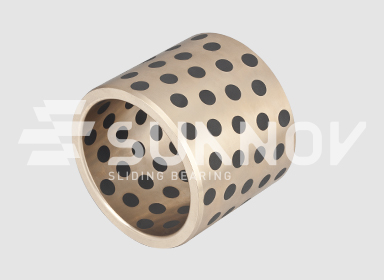

JDB-3 product description

JDB-3 steel-bronze lubricated inlaid bearing is a solid lubricating product in which tin bronze powder is sintered in the base of the steel sleeve and then embedded with solid lubricant. In addition to the functions of JDB-2, it can save costs and improve compressive strength. . Its end face can be welded and installed with the base, so it is suitable for metallurgical machinery, construction machinery and oil transportation machinery and other fields that cannot be refueled.

| code |

JDB-3 |

|

| Material | CuZn25Al5Mn4Fe3+steel+graphite | |

| Density g/cm2 | — | |

| hardness HB | >80~100 | |

| tensile strength N/mm2 | — | |

| Yield Strength N/mm2 | — | |

| Elongation % | — | |

| coefficient of linear expansion 10-5/°C | 1.2 | |

| Thermal Conductivity W(/m.k) | — | |

| Elasticity coefficient KN/mm2 | — | |

| Operating temperature °C |

— |

|

| Maximum dynamic load N/mm2 | — | |

| Maximum line speed m/s | dry rub | — |

| oil lubrication | 1.0 | |

| Maximum PV value N/mm2 · m/s | dry rub | 1.5 |

| oil lubrication | 3.25 | |

| friction coefficient μ | dry rub | 0.12~0.16 |

| oil lubrication | 0.03~0.08 | |

Main application areas

At present, the product has been used in metallurgical machinery, construction machinery and oil transportation machinery and other fields that cannot be refueled.