product description

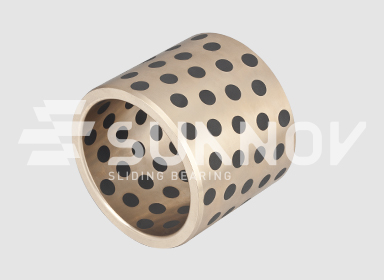

JDB Solid inlaid lubricated bearings use high-strength copper alloy as the base material, and according to the working conditions, holes are machined on the working surface and filled with solid lubricants in a certain proportion.

High-strength copper alloys provide high load-carrying capacity and solid lubricants can form lower friction pairs.

Under dry friction conditions, we design a pre-lubricating film on the bearing surface to ensure that the solid lubricant is transferred to the counterpart in the shortest time and forms an effective solid lubricating film.

Type of material: metal base

| Material correspondence table | ||||||||

| Material code Codes |

China GB1176-87 |

internationality ISO 1338 |

Germany DIN |

Japan JIS |

U.S. ASTM(UNS) |

U.K. BS |

France NF |

Applicable |

| JDB650 High strength alloy copper |

ZCuZn25Al6 Fe3Mn3 |

GCuZn25Al6 Fe3Mn3 |

DIN1709 G-CuZn25Al5 |

H5102 CAC304 |

B30-92 C86300 |

HTB2 | High load, low speed, general use | |

| JDB650 S1 High strength alloy copper |

ZCuZn25Al6 Fe3Mn3 |

GCuZn25Al6 Fe3Mn3 |

DIN1709 G-CuZn25Al5 |

H5102 CAC304 |

B30-92 C86300 |

HTB2 | Ultra high load, low speed, high load | |

| JDB650 S2 Cast tin bronze |

ZCuSn5 Pb5Zn5 |

GCuPb5 Sn5Zn5 |

DIN1705 G-CuSn5ZnPb |

H5111 BC6 |

B30-92 C83600 |

LG2 | CuPb5 Sn5Zn5 |

medium load, low speed |

| JDB650 S3 Cast aluminum bronze |

ZCuAl9Fe4 Ni4Mn2 |

GCuAl10 FeNi5 |

DIN17656 G-CuAl10Ni |

H5114 AlBC3 |

B30-92 C95500 |

AB2 | CuAl10 Fe5Ni5 |

Medium load, medium speed, general use |

| JDB(HT250) cast iron |

GB5675-85 HT250 |

FC250 | ASTM Class40 |

medium load, low speed | ||||

Base material for self-lubricating bearings

| Material composition and properties | |||||||

| Code | JDB650 | JDB650 S1 | JDB650 S2 | JDB650 S3 | JDB650 S4 | JDB (HT250) | JDB (Gcr15) |

| material grade | CuZn25Al6Fe3Mn3 | CuZn25Al6Fe3Mn3 | CuAl9Fe4Ni4Mn2 | CuSn5Pb5Zn5 | CuSn12 | HT250 | Gcr15 |

| density | 8.0 | 8.0 | 8.5 | 8.9 | 9.05 | 7.0 | 7.8 |

| hardness HB | >210 | >250 | >150 | >70 | >80 | >190 | HRC>58 |

| tensile strength N/mm2 | >750 | >800 | >800 | >200 | >260 | >250 | >1500 |

| Elongation % | >12 | >8 | >15 | >10 | >8 | >5 | >15 |

| coefficient of linear expansion 10-5/°C | 1.9 | 1.9 | 1.9 | 1.8 | 1.8 | 1.0 | 1.1 |

| Operating temperature °C | -40~+300 | -40~+150 | -40~+400 | -40~+400 | -40~+400 | -40~+400 | -40~+400 |

| Maximum dynamic load N/mm2 | 100 | 120 | 150 | 60 | 70 | 90 | 200 |

| Maximum line speed m/min (Dry) | 15 | 15 | 20 | 10 | 10 | 8 | 5 |

| Max.PV N/mm2 *m/min | 200 | 200 | 60 | 60 | 80 | 40 | 150 |

| Compression Set 300N/mm2 | <0.01 | <0.005 | <0.04 |

<0.05 | <0.005 | <0.015 | <0.002 |

solid lubricant

| solid lubricant | ||

| solid lubricant | characteristic | Typical use |

| SL1 High Purity Graphite + Additives |

Good wear resistance and chemical stability, Operating temperature<400℃ |

Applied to general machinery, used in the atmosphere |

| SL4 PTFE+additive |

Very low friction coefficient and good water wettability, Operating temperature<300℃ |

It is used in water and seawater lubrication, such as ships, hydraulic arc doors, hydraulic turbines, pharmaceutical and beverage machinery, etc. |

产品优点

● Can be used for a long time without maintenance;

● Designed for very high static and dynamic loads;

● Has a very low and smooth coefficient of friction, no "sticking" phenomenon;

● Has dust resistance, corrosion resistance, impact resistance and edge load resistance;

● The metal substrate has good shock-absorbing ability;

● Can be used in a wide temperature range;

● Suitable for occasions where reciprocating, rotating and swinging are frequently started and it is difficult to form an oil film;

● Has an extremely low wear rate and a long service life.

产品介绍

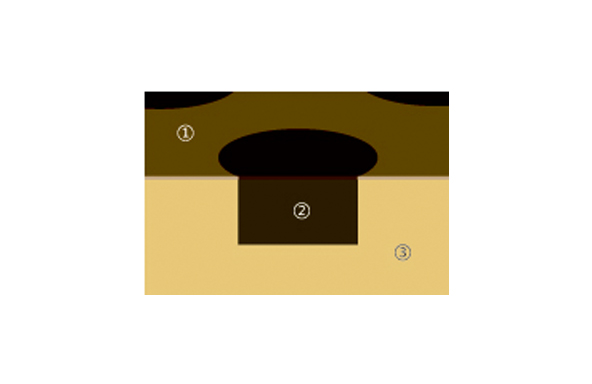

The so-called no oil supply means that there is no need to add oil or less oil. The goal of our research is to ensure that the bearing can still perform well under this working condition and prolong its service life as much as possible. The basic working principle of self-lubricating bearings is that in the initial running stage, the solid lubricant on the bearing surface forms a transfer film due to mutual friction and coats the opposite abrasive parts to form a solid lubricating film to achieve the purpose of self-lubricating. The direct contact between the workpieces thus protects the abrasive parts and prolongs the service life of the bearing and the workpiece.

Bearing characteristics

Modern designs are placing huge demands on today's self-lubricating bearing materials. Maintenance-free is required even in severe extreme operating environments and maximum load conditions. With the continuous improvement of cost requirements, enterprises have higher and higher requirements for the reliability of equipment and plant operation. Metal self-lubricating bearings can meet maintenance-free and self-lubricating conditions under long-term use conditions, thus making it possible to design a reliable long-term self-lubricating system. Metal type self-lubricating bearing materials can be widely used in rotation, oscillation and linear reciprocating motion under high load and low speed conditions, and also suitable for occasions where traditional lubrication cannot be achieved or prohibited, or in special working conditions such as dust, impact Long-term and stable use under load or irradiation conditions.

Application

Products are widely used in continuous casting and rolling mills, injection molding machinery, automobile molds, bridge machinery, water conservancy industry, steel rolling equipment, mining machinery, construction machinery, communication, steam turbines, manipulators, offshore oil platforms, etc.