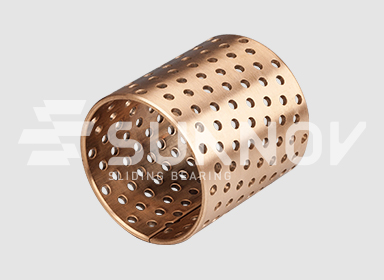

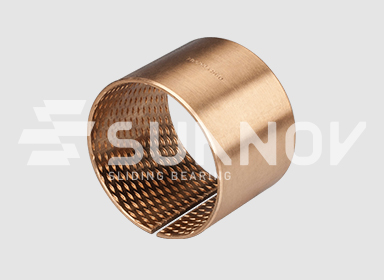

FB092 product description

FB092 Bronze Rolled Bearings are made of bronze material as the base body, machined with uniform and orderly oil injection holes, and rolled thin-walled bearings. After assembly, lubricating grease is injected, and then the end face seals are arranged for use. The bearing has the advantages of large oil storage, convenient installation and small design volume, and can be used in place of copper sleeves, which can greatly reduce costs.

| code |

FB092 |

|

| Material | CuSn8 | |

| Density g/cm2 | 8.8 | |

| Max dynamic load N/mm2 | 40 | |

| Maximum Linear Speed (Grease Lubrication) m/s | 2.5 | |

| Maximum PV value (grease lubrication) N/mm2 · m/s | 2.8 | |

| tensile strength N/mm2 | 460 | |

| Yield Strength N/mm2 | 260 | |

| Hardness HB | 90~150 | |

| Adapt to temperature range °C | -40~150 | |

| friction coefficient μ | 0.06~0.15 | |

| Thermal Conductivity W(/m.k) | 58 | |

| Linear expansion coefficient (axial) | 18.5✕10-5 /k | |

| Matching shaft | Hardness HRC | ≥50 |

| Roughness Ra | 0.4~1.0 | |

Main application areas

At present, the product has been used in medium-load and low-speed occasions such as conveyors, elevators, rolling machines, and leveling machines.